ECE students excel at Engineering Design Expo

intro and telematics

On April 19, hundreds of UIC College of Engineering students participated in the UIC Engineering Design Expo at the Credit Union 1 Arena. The Expo is the culmination of the Senior Design Course, and features teams from across the College of Engineering (COE). Over 150 judges, including Chicago-area engineering professionals, alums, and former COE faculty took part this year. Here are some of this year’s projects from the electrical and computer engineering department:

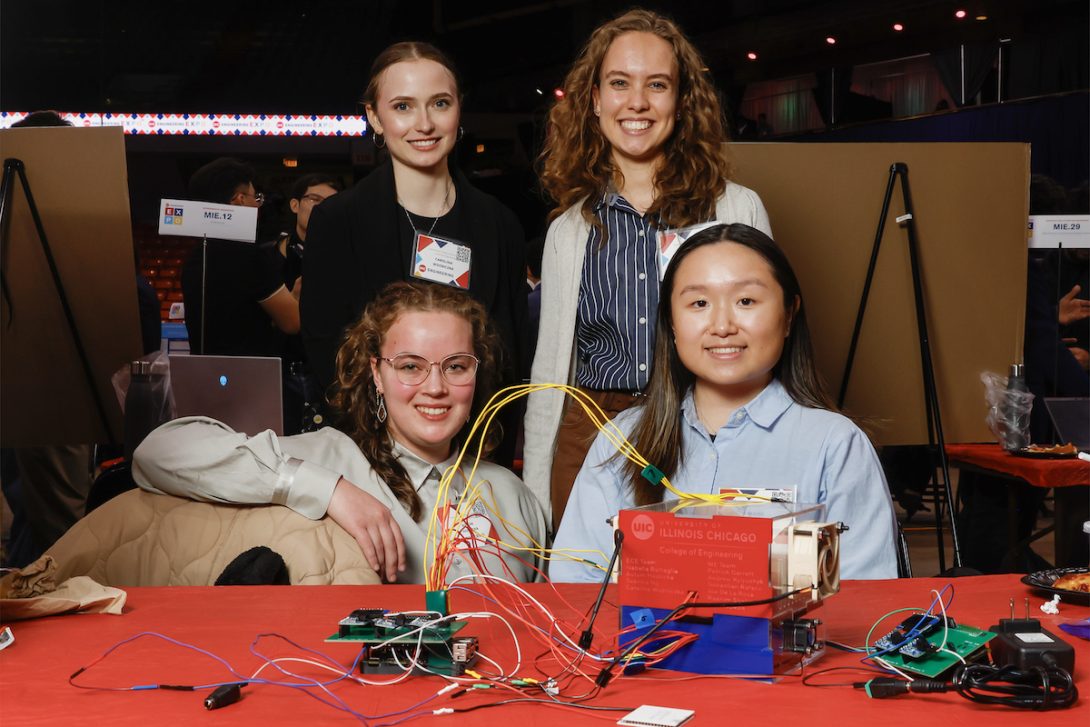

Telematics Cooling System and Testing Environment

Isabella Battaglia, Autum Hosticka, Sabrina Ng, and Carolina Wozniczks developed a cooling system for automotive telematics, the telecommunications and infomatic devices that provide navigation, roadside assistance, and vehicle diagnostics to drivers, and allow drivers to answer calls and passengers to watch movies.

Working with an OEM telematics provider who sponsored the project, the team designed a testing environment that simulates hot environments – up to 120 degrees Fahrenheit – like car interiors on hot days, to evaluate the impact of these environments on the telematics. They created cooling chambers and measured their ability to lower chip temperatures. The team met with their sponsor weekly.

They ran the chips at 5.5 watts with no cooling to establish a control case for heat produced, then ran cooling algorithm experiments with the fans and Peltier to compare to the control. They monitored power consumption during use of their cooling system, which included bottom cooling fans, upper cooling fans, and a Peliter unit, a device that sends an electric current through a junction between two types of materials, which causes a temperature differential that can be used to cool or heat the junction, depending on the direction of the current. They included multiple temperature sensors in their testing environment.

The system they designed was able to stabilize and cool the chips over a short period of time. The bottom fans managed to hold the temperature steady, and the top fans and Peltier unit could lower the temperature.

The group hopes one of next year’s Expo teams can continue their research on telematics devices.

G Force tracker

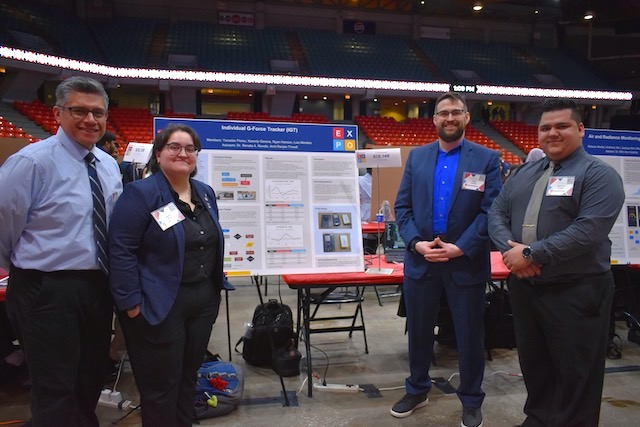

Individual G-Force Tracker

Ryan Hanson served as an electronics technician in the Coast Guard for over 18 years, so when he and his ECE teammates Yaro Florov, Karenly Gerena, and Luis Morales were considering options for their capstone project, they turned to the Coast Guard.

One of the research ideas they found was to develop a tool that would provide real-time data on shock impacts, as Coast Guard personnel operate in challenging environments aboard a variety of vessels. Hanson understands these risks all too well; he has several bulging discs in his back because of his service.

The group created a wearable for the back of soldier’s helmets, which includes an inertial measurement unit and an Arduino. They developed code to record acceleration and tested the unit by simulating shocks and converting these figures to G-force values.

The group said it took subsequent iterations of their original idea but that they ultimately were successful in developing a working prototype, which they will present to the Coast Guard this month.

composter

Air Pro Max Smart Composter

The team behind the Air Pro Max Smart Composter drew inspiration from Alejandro Flores’ wife’s love of gardening. Flores, Jonathan Leyva, Trino Jaime, and Ali Mohamed took an off-the-shelf composting bin, and fitted it with sensors, an automatic spin device, and a digital readout to assist gardeners new to composting.

Compost is a nutrient-rich soil-like material, composed of decomposing organic material such as leaves, grass clippings, and vegetable scraps. The most effective way to produce rich compost is to create a hot or active compost pile, which will destroy weed seeds and pathogens in the compost. The temperature must be between 110 and 140 degrees Fahrenheit, and nitrogen can be added to bring up the temperature. After the material has been “cooked” the pile starts to cool down naturally. Knowing when to turn the compost to add oxygen, and determining whether the compost is fully processed often vexes those new to the process.

The team designed custom parts to assess the compost during processing, and automatically turn the bin as needed. They created their kit for about $200.